Crane Track Roller

Basic Information of Crawler Crane Track Roller

What is a crawler crane track roller?

Crawler crane bottom rollers are located on the lower part of the undercarriage, above the trackpads. They support the entire structure and are used to support and guide the crawler tracks as the crane moves. Crawler crane track roller helps to evenly distribute the weight of the crane across the tracks, reducing friction and making the crane move more smoothly across the ground. These crawler bottom rollers are essential to ensure that crawler cranes operate efficiently, allowing them to travel over rough terrain without excessive wear on the crawler track shoes.

Material

Crawler bottom rollers are usually made of high-strength materials, which have excellent strength, durability, and wear resistance. The specific steel grade and composition may vary depending on the manufacturer and the requirements of the roller. Generally speaking, most crawler crane track roller bodies are made of 40Mn2. Some large-tonnage track roller bodies are made of 42CrMo, which can increase hardness and toughness.

| Product Name | Chemical Analysis | |||||||

| LR1300 Bottom Roller | C(%) | Si(%) | Mn(%) | Cr(%) | Ni(%) | P(%) | S(%)) | Cu(%) |

| 0.41 | 0.25 | 1.52 | 0.15 | 0.01 | 0.015 | 0.01 | 0.02 | |

Search Products

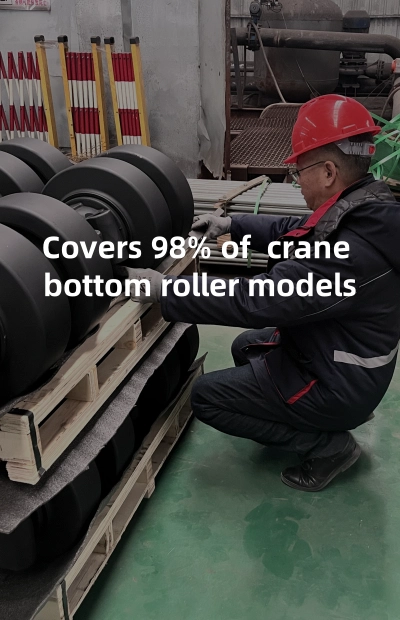

VM® Crawler Track Roller

For the crane bottom roller, VM is able to provide more than 20 models such as kobelco, liebherr, hitachi, Sumitomo, Manitowoc, IHI, Link Belt, Sharyo Nippon, XCMG, SANY, Zoomlion, etc.

Superior corrosion resistance

Customized service

Sufficient stock

Crane Track Roller Supplier

Sumitomo Bottom Roller

- Product Name: Bottom Roller for Sumitomo Crawler Crane

- Brand: VM

- Available Models: LS78RH, LS98, LS108RH5, LS118, LS138, LS248RH5, LS368RH5, LS458HD, LS518, SC350, SC400, SC500, SC500-2, SC550, SC650, SC700, SC900, SC1000, SC1500, SC2000, etc.

Terex Demag Track Roller

- Product Name: Track Shoe for Terex Demag Crawler Crane

- Brand: VM

- Introduce: Terex Demag track shoes pay attention to the details of the parts. We have added boring holes to improve the coaxiality of the pin holes, as well as connection inspection after production. In this way, the trackpads with more even force will not be easily deformed, thus reducing your maintenance costs.

- Available Models:CC200, CC280, CC280-1, CC400, CC400C, CC600, CC1000, CC1100, CC1200, CC 1500, CC 1800, CC 2000, CC2000-1, CC 2200, CC2400, CC2500, CC2600, CC 2800, CC 3800, CC4000, SL3800, CC 6800, CC 8800

XCMG Bottom Roller

- Product Name:Bottom Roller for XCMG Crawler Crane

- Brand: VM

- Available Models: QUY50, QUY70, QUY80, QUY100, QUY150, QUY250, QUY260, QUY280, QUY300, QUY350, QUY400, QUY450, QUY650, QUY700, QUY1000, XGC85, XGC100, XGC130, XGC150, XGC180, XGC200, XGC260, XGC350, XGC650, XGC15000, XGC28000, etc.

Zoomlion Track Roller

- Product Name:Bottom Roller for Zoomlion Crawler Crane

- Brand: VM

- Available Models: QUY70, QUY100, QUY130, QUY260, QUY350, QUY500W, QUY550, QUY650, QUY1000, ZTM300, ZTM500, ZCC550, ZCC750H, ZCC800, ZCC850, ZCC1100 H, ZCC1800HWG, ZCC2600CR, ZCC3800, ZCT600V etc.

How to Replace Crane Track Rollers

Tools and Equipment Required:

Hydraulic Jack or Track Jack, Wrench and Socket (Appropriate Size), Lifting Equipment (If Needed), Replacing Track Rollers, Crowbar or Prybar, Safety Equipment (Gloves, Helmet, Safety Shoes), Lubricant (Optional for Bolt Threads)

Safety First

Make sure the crane is off and all power is disconnected. If necessary, stabilize the crane using safety stands, especially if you plan to raise the machine for better access.

Raise and Secure the Crane

Raise the crane off the ground using a hydraulic jack or track jack, focusing on the side where the track roller needs to be replaced. Check for stability and never work under a raised crane without proper support.

Remove Track Tension

If the crane uses an adjustable track tension system, loosen the tensioning bolts or valve to release track tension. This will make it easier to remove the track rollers.

Remove the Crawler Crane Track Roller

Locate the bolts or fasteners that hold the track roller in place. Use an appropriate wrench or impact tool to loosen and remove the bolts. If the crawler crane track roller is stuck due to dirt or rust, you may need to use a pry bar or crowbar to help loosen the crane bottom roller. After removing the bolts, carefully remove the track roller from its bracket. Depending on the size and weight, you may need additional lifting equipment to help with this operation.

Prepare the New Track Roller

Before installing the new crawler crane track roller, inspect the mounting point for any debris, dirt, or wear. Clean the area if necessary.

Install the New Roller

Place the new crawler crane track roller in place, making sure it aligns with the mounting holes on the track frame. Insert the bolts and tighten them into place using a wrench or impact tool. Make sure to torque the bolts to the manufacturer's specifications. If necessary, apply a small amount of lubricant to the bolt threads to aid in future removal and prevent corrosion.

Adjust Track Tension

Reapply track tension if it was previously released. Tighten the tensioning bolts or valve according to the crane's operating manual.

Check the installation

Verify that the crawler crane track rollers are operating properly by rotating the tracks or moving the crane a short distance.

Lower the crane

Use a hydraulic jack or track jack to carefully lower the crane back to the ground. Remove any safety brackets or lifting equipment.

Test the crane

Once the crane is back on solid ground, perform a brief test to ensure that the crane bottom rollers are operating smoothly with no unusual noises or movements. Check the surrounding area for signs of oil leaks or loose bolts.

Crane Parts Delivery