Crane Track Shoe: Reliable Undercarriage Support from a Professional Supplier

For crawler cranes, the track shoes play a crucial role in the machine’s overall operation. They are not merely steel plates attached to the track chain, but critical structural components that influence traction, load balance, and long-term reliability.

As a professional manufacturer of crane components, we have 28+ years of production experience. Precisely manufactured track pads ensure smooth crane operation in demanding environments.

What are crane track shoes?

Track shoes are an important part of the crawler undercarriage. Track shoes are assembled with pins, bolts, and nuts to form a track shoe assembly. This track shoe assembly supports the entire track frame and allows the crane to operate smoothly.

The main function of the track pads is to ensure that the enormous weight of the crane is evenly distributed, to provide sufficient traction to guarantee safe movement, and to effectively protect other undercarriage parts from excessive wear. Since the track shoes are the only components in direct contact with the ground, their strength and durability are crucial for the safe and efficient operation of the crane.

Different Types of Track Shoes

Crawler cranes are operated in different working conditions, and track shoes are designed in several forms to meet specific conditions.

Standard Flat Track Shoes

Flat track shoes are the common type, like Manitowoc 4100 track shoe, Link-belt LS278 track pad, and Kobelco CKE1800 track shoe. They provide a large contact area and are suitable for general construction sites with relatively firm ground.

Double Grouser Track Shoes

These track shoes can enhance grip. They are ideal for use on uneven or soft ground to provide extra traction.

Triple Grouser Track Shoes

Common types of track shoes used on excavators, such as the Hitachi EX100-5 excavator track shoe. This design provides the strongest traction and stability. It is often used on soft soil, steep slopes, or complex terrain.

Each design has its own advantages. So it is essential to choose the suitable type of track shoe based on working conditions. It will help extend the lifespan of the undercarriage and improve the efficiency of the crane.

Material Selection: A Key Factor in Extending Service Life

The performance of crane track shoes begins with their material. Choosing the right material ensures that the track shoes can withstand heavy loads and harsh working environments.

In our manufacturing process, we typically use the following proven steel grades:

35SiMn

This is a reliable material suitable for general use. It offers good mechanical strength and toughness, making it ideal for medium-sized crawler cranes.

31Mn2Si

This manganese-silicon alloy steel exhibits excellent wear resistance and structural stability. It performs exceptionally well under continuous operation and regular construction conditions.

31Mn2SiMo

This grade of material is widely used for heavy-duty crawler crane track shoes subjected to higher stresses.

31Mn2SiMoNi

With the addition of nickel to the alloy, this material possesses excellent toughness and impact resistance. It is often used for large-tonne cranes and in demanding work environments.

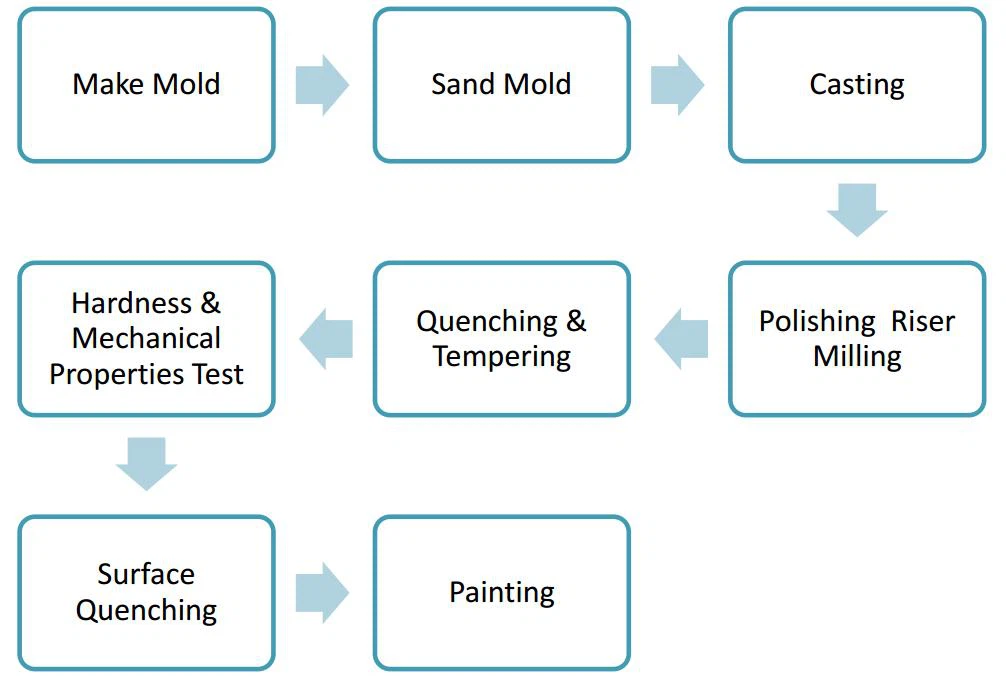

After material selection, all track shoes undergo a strictly controlled heat treatment process. Quenching and tempering are employed to achieve the required hardness and structural strength, ensuring stable performance in practical applications.

Professional Production Experience

As an experienced crane component manufacturer, we manage the entire production process. From raw material preparation to final inspection, every step follows standardized operating procedures to ensure consistent product quality.

Production Process

Raw Material

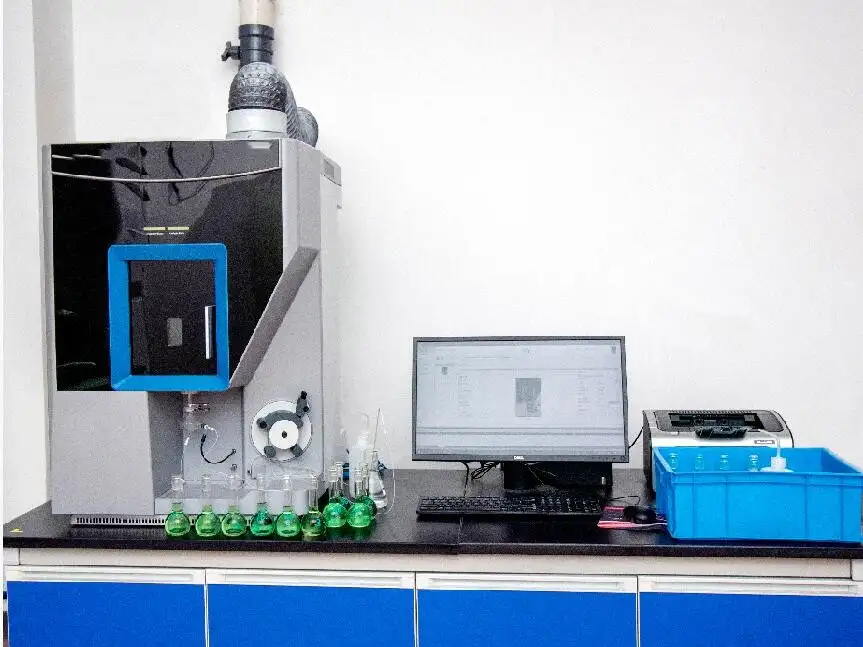

All steel materials entering the production line undergo testing for chemical composition and mechanical properties before being used in production.

Casting

Track shoes are manufactured through a casting process to achieve the required shape and strength.

Heat Treatment

Controlled heating and cooling processes improve the material’s hardness, toughness, and overall durability.

Precision Machining

CNC equipment is used to maintain precise dimensions and ensure proper fit with pins and other undercarriage components.

Surface Treatment

Surface painting can be applied to improve the appearance.

Strict Quality Control and Testing

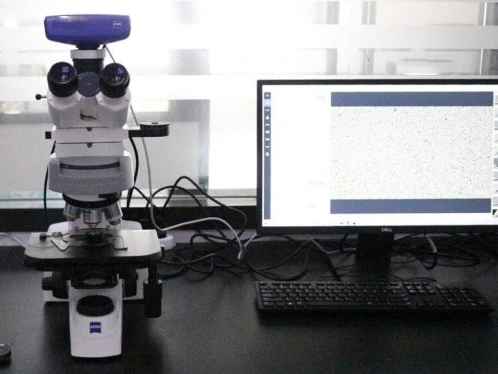

For crawler crane undercarriage parts, strict quality control is crucial because these parts must withstand heavy loads and maintain continuous operation. We will do rigorous inspections before shipment to ensure that every part meets technical standards. Our main testing methods are Nondestructive Testing and Destructive Testing:

| Nondestructive Testing | Destructive Testing |

| Chemical Test | Metallographic Analysis |

| Visual Inspection | Hardness Testing |

| Dimensional Inspection | Tensile Testing |

| Dye Penetrant Testing | Impact Testing |

| Wet Magnetic Particle Testing | |

| Ultrasonic Testing |

Only products that have passed all inspection stages are approved for delivery to customers.

Key Specification Table: Crane Track Shoe Metrics

| Attribute | Standard Range | Remarks |

| Material Grade | High-strength alloy steels | Custom grades available |

| Hardness Range | 28–34 HRC (typical) | After heat treatment |

| Grouser Style | Flat / Double / Triple | Based on terrain needs |

| Production Method | Casting | Determined by part size |

| Fitment Compatibility | Multiple crawler crane models | Including Link-Belt crane parts, Liebherr crane parts, Kobelco crane parts, Manitowoc crane parts, Demag crane parts, Hitachi crane parts, Sumitomo crane parts, SANY crawler parts, XCMG crawler parts, IHI crane parts, Terex crane parts |

Advantages of Choosing VM® Undercarriage Parts

Choosing VM® crawler crane undercarriage parts offers several distinct advantages:

1. In-depth Material Knowledge

We understand the impact of different steel grades and heat treatments on product performance, which helps customers obtain more durable track shoes.

2. Customized Production

Whether you have an inquiry for special sizes, we can manufacture the parts according to your drawing with your technical requirements.

3. Reliable Quality Control

Controlling the entire production process allows us to maintain consistent and reliable quality.

4. Technical Support

We provide guidance on installation, maintenance, and parts selection, which aims to help customers reduce downtime and lower operating costs.

Conclusion

The track shoes of crawler cranes are one of the most critical components of their undercarriage. Their quality directly impacts the machine’s stability, safety, and overall operating costs. As a trusted manufacturer of crane components, we are committed to providing high-performance crawler crane parts to customers worldwide. We can produce undercarriage parts for 97% of worldwide brands of crawler cranes, ranging from 30 tons to 1350 tons, including Kobelco, IHI, Nippon Shayo, Manitowoc, Liebherr, Sany, Zoomlion, Terex, Demag, Hitachi, Sumitomo, FUWA, XCMG, and so on.