Demag Crawler Crane Undercarriage Parts

Welcome to KNOW about the Demag Crane undercarriage parts

Demag crawler cranes have a rich history in the crane industry, known for their innovation and reliability. The brand originated in 1910 through the merger of several engineering companies in Germany, and it quickly became a leader in industrial machinery. One of Demag’s flagship crawler crane models is the CC 8800-1, capable of lifting to 1,600 tons. These cranes are widely used in heavy-duty industries such as construction, energy, and infrastructure projects.

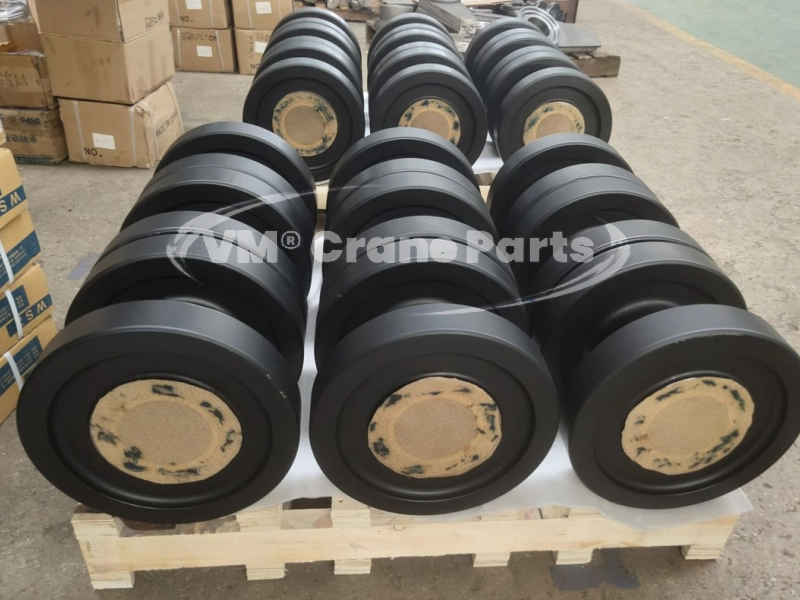

With over 28 years of experience, our company has built a reputation as a trusted and reliable supplier of Demag crawler crane undercarriage parts for clients across the industrial, infrastructure, power, and commercial sectors. No matter the size of your Demag crawler crane, we provide the high-quality Demag crawler crane undercarriage parts you need to ensure smooth and efficient crane operation. From Demag crane track shoes to Demag rollers and Demag idlers, our high-quality Demag crawler crane undercarriage parts are designed to meet the toughest demands, ensuring your crane performs safely and reliably on every job.

Demag Model

CC200, CC280, CC280-1, CC400, CC400C, CC600, CC1000, CC1100, CC1200, CC 1500, CC 1800, CC 2000, CC2000-1, CC 2200, CC2400, CC2500, CC2600, CC 2800, CC 3800, CC4000, SL3800, CC 6800, CC 8800

Best Choice

Chemical Composition Testing: Before production, each batch of raw materials must undergo strict chemical analysis. The content of key elements such as carbon, silicon, manganese, and chromium will be tested to ensure that the high-quality Demag crawler crane undercarriage part has sufficient hardness and durability

Dimensional Accuracy: During production, all Demag crawler crane undercarriage parts are manufactured to tight tolerances to ensure a perfect fit with Demag crawler cranes. Precise measurements are taken at every process of production, including initial forging, machining, and final assembly.

Mold Casting Precision: Raw materials are carefully cast into molds designed for each specific Demag crawler crane undercarriage part. Any deviations at this stage may affect the function and service life of the part.

Quenching and Tempering: Heat treatment is used to increase the mechanical strength of Demag crawler crane undercarriage parts. The process involves hardening through controlled heating and rapid cooling to ensure the high-quality Demag crawler crane undercarriage part can withstand heavy loads and continuous use. This is followed by tempering to increase toughness and reduce brittleness.

Thermal Testing: After heat treatment, Demag crawler crane undercarriage parts are tested for thermal stability to ensure they can operate under various temperature conditions without deformation or cracking.

Probe Testing: This method detects internal defects that may not be visible from the outside, such as cracks or inconsistencies in the material. It ensures that every high-quality Demag crawler crane undercarriage part is structurally supported when shipped from the factory.

Magnetic Particle Inspection: Another non-destructive testing technique used to find surface and micro-subsurface discontinuities to ensure Demag crawler crane undercarriage part reliability under reassembly.

Chemical Composition Testing: Before production, each batch of raw materials must undergo strict chemical analysis. The content of key elements such as carbon, silicon, manganese, and chromium will be tested to ensure that the high-quality Demag crawler crane undercarriage part has sufficient hardness and durability

Dimensional Accuracy: During production, all Demag crawler crane undercarriage parts are manufactured to tight tolerances to ensure a perfect fit with Demag crawler cranes. Precise measurements are taken at every process of production, including initial forging, machining, and final assembly.

Mold Casting Precision: Raw materials are carefully cast into molds designed for each specific Demag crawler crane undercarriage part. Any deviations at this stage may affect the function and service life of the part.

Quenching and Tempering: Heat treatment is used to increase the mechanical strength of Demag crawler crane undercarriage parts. The process involves hardening through controlled heating and rapid cooling to ensure the high-quality Demag crawler crane undercarriage part can withstand heavy loads and continuous use. This is followed by tempering to increase toughness and reduce brittleness.

Thermal Testing: After heat treatment, Demag crawler crane undercarriage parts are tested for thermal stability to ensure they can operate under various temperature conditions without deformation or cracking.

Probe Testing: This method detects internal defects that may not be visible from the outside, such as cracks or inconsistencies in the material. It ensures that every high-quality Demag crawler crane undercarriage part is structurally supported when shipped from the factory.

Magnetic Particle Inspection: Another non-destructive testing technique used to find surface and micro-subsurface discontinuities to ensure Demag crawler crane undercarriage part reliability under reassembly.

F.A.Q for Demag Crane Undercarriage Parts

If your Terex crane is under warranty, contacting the manufacturer or a certified service provider is usually the best way to source replacement high-quality Demag crawler crane undercarriage parts. However, in cases where warranty claims or service calls lead to delays, you may need a faster solution.

We are here to help.

With some of the quickest response times in the industry, we offer a wide selection of high-quality undercarriage parts for Terex crawler cranes. Whether you need track shoes, rollers, idlers, or sprockets, our inventory is designed to minimize machine downtime and maximize your crane’s productivity.

All we need from you is your crane’s year, model, and description of the high-quality Demag crawler crane undercarriage part you need. Rest assured, we’ll source the exact part to keep your machine running smoothly.

Contact us by email, and we will contact you within 1 hour with detailed information that you need.

For optimal crane maintenance, OSHA and manufacturer operating manual safety standards must be followed. While OSHA requires annual inspections by a certified professional, regular maintenance is necessary to keep your crane in top overview condition:

- After work, check whether components such as chains, track shoes, lower roller, idler, and connecting parts are faulty.

- Check the position condition before lifting to ensure safe operation.

- Inspect the hook after use of the terminal to confirm that it is not worn or damaged.

- Monitor air and hydraulic systems daily as floor plans and piping are prone to leaks or damage.

- As soon as operational fatigue becomes apparent, replace South Africa and track immediately, Palestine is inefficient.

The Feedback Of Demag Crane Undercarriage Parts

Peter Johnson – Nov. 1, 2023

“Our team installed new rollers on our Demag CC1800, and they are holding up well under tough working conditions. The high-quality Demag crawler crane parts are solid, and we appreciate the attention to detail in the production.”

Laura Smith – August 25, 2024

“The idlers we ordered for our Demag crawler crane arrived on time and were incredibly durable. Excellent service and quick responses from the support team made the process smooth.”

Mark Thompson – September 12, 2024

“We recently replaced the track shoes on our Demag CC2800-1 crawler crane, and the quality of the Demag crawler crane undercarriage part exceeded our expectations. The parts were a perfect fit, and the crane’s performance has improved significantly.”