-

By cranecrawler.com

- 0 Comment

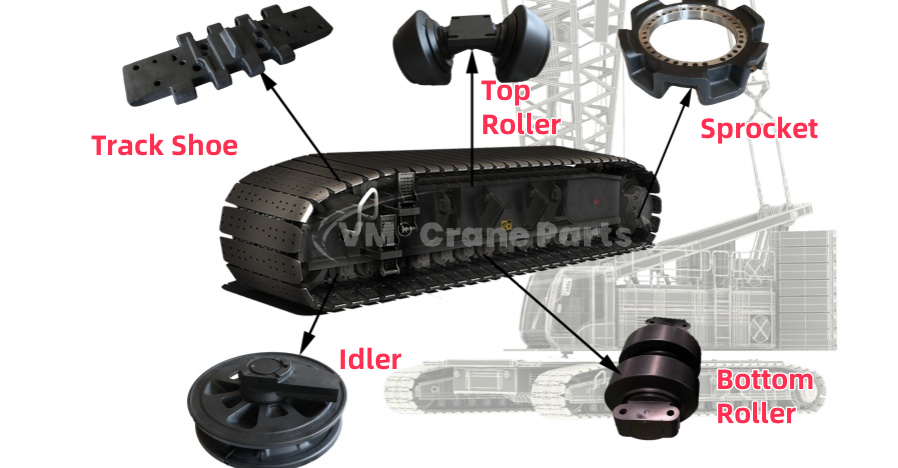

Guide to the Proper Use of Crawler Crane Sprockets

Crawler crane sprockets are a critical component that transmit power from the travel motor to the crawler system, enabling smooth movement over varying terrain. To maximize performance and prevent premature wear, operators must follow best practices in installation, maintenance, and material selection. The following is a detailed guide on how to properly use of crane sprocket.

1. The Importance of Track and Sprocket Alignment

Misalignment between the sprocket and the track can lead to uneven wear, increased friction, and potential system failure. To ensure proper alignment:

- Check track tension regularly and adjust to manufacturer’s specifications.

- Check for uneven wear on the sprocket teeth, which may indicate misalignment.

If necessary, use a laser alignment tool or professional alignment service.

2. Choose the Right Sprocket Material

The material of the sprocket directly affects its durability and wear resistance. High-quality sprockets like those made from 35SiMn alloy steel have excellent strength and fatigue resistance. Key considerations include:

- Heat treatment: Induction-hardened sprockets can withstand heavy loads and abrasive conditions.

- Corrosion resistance: If operating in a wet or corrosive environment, choose a sprocket with a protective coating.

- Manufacturing precision: Make sure the sprocket meets industry standards (such as ISO 9001 certification) for dimensional accuracy.

3. Effective Use of Crane Sprocket: Wear Monitoring Techniques

Sprockets are under constant pressure, especially in harsh conditions. Implement a proactive inspection program:

- Inspect worn teeth: Look for signs of rounding, chipping, or elongation.

- Lubrication: Apply high-quality grease to sprocket teeth to reduce friction and prevent premature wear.

- Cleaning: Remove debris, mud, and rocks from the track and sprocket to avoid wear.

4. Replacement criteria

Hard indicator: Tooth height wear exceeds 10% (for example, if the original tooth height is 50mm, it must be replaced if it is 45mm).

Soft indicators: The following conditions should be replaced even if the wear limit is not reached:

- Cracks on the tooth surface

- Some teeth are chipped

- Regular “clicking” noise during operation

5. Correct installation techniques

Incorrect installation can lead to inefficient operation and mechanical failure. Please follow the steps below:

- Safe installation: Make sure the sprocket is firmly fixed to the travel motor shaft.

- Torque specifications: Use the bolt torque value recommended by the manufacturer to avoid loosening.

- Alignment verification: After installation, manually rotate the track to confirm smooth engagement.

For complex installations, please consult the equipment manual or seek professional help.

6. Efficient Use of Crane Sprocket: Load & Depth Specifications

Different applications require specific sprocket configurations:

Deep-Toothed Sprockets

Data reference:

- Tooth depth 10-15mm deeper than standard sprockets

- Applicable load 50-800 tons Cranes

- Applicable ground Soft soil, clay, sand (ground bearing capacity <0.3MPa)

Advantages:

- Deeper tooth grooves (usually 15-20% deeper than standard sprockets) can enhance the meshing with the track shoes and reduce the risk of slipping.

- Applicable to heavy cranes over 40 tons, with a 20-30% increase in traction efficiency in muddy ground.

- Usually made of high-strength alloy steel (such as 42CrMo), the tooth surface is high-frequency quenched (hardness up to HRC55-60), which is more wear-resistant.

Standard Sprockets

Data reference:

- Tooth Depth 50-70mm

- Applicable Load 10-50 tons Crane

- Applicable Ground Hardened Road, Gravel Ground (Ground Bearing Capacity >0.5MPa)

Advantages:

- Lower tooth height (usually 50-70mm), smoother operation, suitable for high-speed movement (travel speed can reach 1.5-2.5km/h).

- Generally, using 35SiMn or 40Cr materials is more economical.

- Low maintenance cost, suitable for long-term continuous operation.

7. Benefits of Proper Sprocket Maintenance

Following these best practices can bring multiple benefits:

- Extended equipment life: Reduced wear on crawler, motor, and chassis components.

- Cost savings: Minimize unplanned downtime and expensive repairs.

- Operational efficiency: Ensure smooth crane movement and precise load handling.

Proper use and maintenance of crawler crane sprockets is essential for reliable performance. By prioritizing alignment, material quality, regular inspections, and proper installation, operators can improve durability and operational efficiency. Implementing a structured maintenance program will maximize uptime and return on investment for heavy lifting operations.