How to Choose Different Types of Crane Hooks?

As the core lifting device of a crawler crane, the crawler hook directly determines the safety and accuracy of lifting operations. How to choose and use the right types of crane hooks effectively? This article combines frontline construction experience with the latest industry standards to provide you with practical tips.

Why is the crawler hook considered the “lifeline” of crawler crane safety?

Crawler cranes, with their low ground pressure, large lifting capacity (commonly 80-2000 tons), and ability to travel with loads, are widely used in heavy-duty projects such as wind turbine tower hoisting and petrochemical reactor installation. The crawler hook, as the final link between the crane and the load, must withstand dynamic loads, torsional shock, and even sudden eccentric loads. Its reliability directly impacts the overall situation:

Types of Crane Hooks and Suitable Applications

1. Large-tonnage Forged Double Hook (Main Application: 200 tons and heavier lifts)

Features: The double hooks symmetrically share the load, reducing stress concentration on one side. The hook body is forged from chromium-molybdenum alloy steel (tensile strength ≥ 1200 MPa).

Suitable for: Wind turbine towers (single section weighing 300-800 tons), large petrochemical reactor hoisting.

2. Single Hook + Anti-Unhooking Lock (General Purpose: 50-300 tons, general operations)

Features: The single hook features a simple structure and light weight, equipped with a positive locking anti-unhooking device (mandatory under OSHA/GB standards) to prevent accidental wire rope slippage.

Suitable for: Medium-tonnage operations such as steel structure factory beam hoisting and equipment relocation.

Purchasing Note: Be sure to confirm the anti-unhooking lock’s “self-locking angle” (preferably ≥15°) to prevent vibration-induced unlocking.

3. Plate-Type Combination Hook (Customized: Special-Shaped Loads/Extra-Wide Lifting Points)

Structure: The hook body is welded from multiple thick steel plates. The hook mouth size can be adjusted to suit the shape of the load’s lifting lugs (e.g., round or square).

Applicable Scenarios: Nuclear power equipment (non-standard lifting lugs), bridge section lifting (irregular center of gravity).

Advantages: More flexible than forged hooks, but welds require regular inspection (key area: the connection between the hook mouth and the main plate).

4. Rotating Hook (Special Condition: Under-load slewing requirements)

Technology: Built-in double-row tapered roller bearings allow the load to rotate freely ±360° during the lifting process (e.g., aligning wind turbine blades with tower connections).

Applicable Scenarios: Offshore wind turbine blade installation, large billboard installation.

Maintenance Key Points: Monthly, check the bearing grease condition (high-temperature lithium-based grease is recommended). Immediately shut down the machine if any abnormal noise is detected.

5. Intelligent Monitoring Hook (Advanced Model: Standard for high-end projects in 2025)

Functions: Integrated strain sensor (real-time monitoring of hook force), tilt sensor (detection of off-load angle), and wireless transmission module (data synchronized to the cab display).

Applicable Scenarios: Extremely hazardous and large projects (such as the main arch installation of a cross-river bridge), and foreign-funded projects (where the owner mandates safety requirements).

Data Value: Analyzing historical load curves can provide early warning of hook fatigue damage (with an error rate of <3%).

Three-Step Method for Selection of Types of Crane Hooks Selection

Step 1: Identify Basic Parameters

Maximum Load: The hook’s rated load must be ≥ the actual load × 1.25 (safety factor, as required by GB/T 20118);

Lifting Point Spacing: The hook width must match the load lug size (with an error of ≤5mm). Custom widening of the hook is available if necessary.

Step 2: Matching the Working Conditions

For high-frequency vibration scenarios (e.g., high-altitude assembly of steel structures): Prefer anti-unhooking locks with rubber cushions.

For multi-angle lifting (e.g., cable-stayed bridge towers): Choose a forged hook with a strong hook body to prevent deformation during luffing.

For coastal/chemical environments: Choose a rust-resistant hook body that is galvanized or spray-coated with PTFE (salt spray test ≥ 1000 hours).

Step 3: Verifying Compatibility

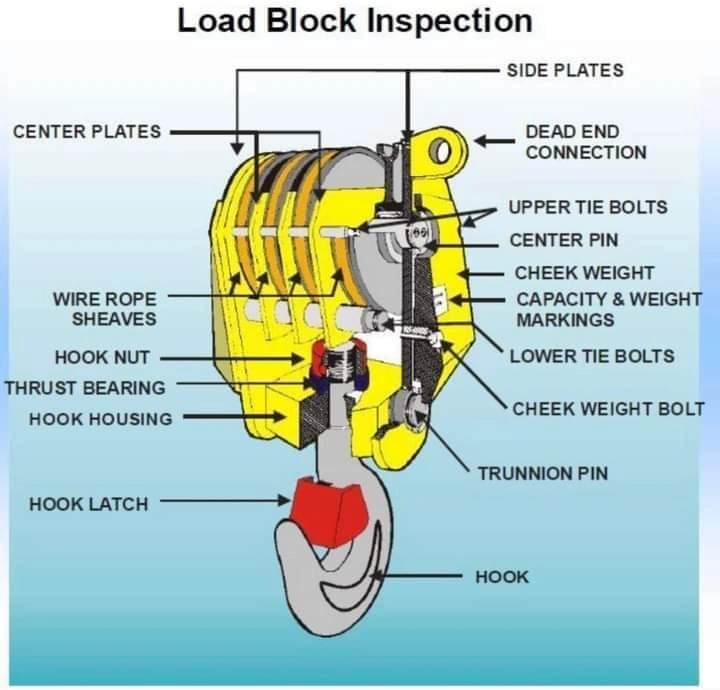

Matching with the lifting equipment: Confirm the attachment method (pin diameter, cotter pin specifications) for the hook and the crawler crane’s hook pulley assembly (e.g., single pulley, double pulley).

Compatibility with the wire rope: The hook opening must be larger than 1.5 times the wire rope diameter to prevent crushing damage.

High-Frequency Faults and Solutions

Fault 1: Abnormal Hook Mouth Wear

Cause: The load wire rope slides and rubs within the hook mouth (especially during frequent lifting and lowering).

Solution: Install a wear-resistant bushing (manganese steel or polyurethane) or use a hook with a “rope guide groove” (to guide the wire rope in place).

Fault 2: Anti-hook lock failure

Typical symptoms: The lock tongue automatically rebounds after vibration, posing a risk of load slippage.

Checkpoints: Check for fatigue in the lock tongue spring (press to test the rebound strength) and for sticking in the latch hinge (lubricate with lithium-based grease).

Fault 3: Hook cracks

Detection method: Visually inspect the hook weekly (focusing on the hook tip radius and the inside of the hook mouth). Perform a monthly deep inspection with a magnetic particle detector.

Warning sign: Small linear marks appear on the hook surface (possibly an early sign of cracks).

Maintenance

Before daily operation: Check hook wear (measure the opening with a caliper and compare it to the initial value) and the locking status of the anti-unhook lock.

Weekly: Clean the hook surface (especially welding slag and sand), and lubricate the bearings (swivel hook) and pins.

Monthly: Perform a comprehensive flaw detection (magnetic particle/ultrasonic) and record the number of hook lifts (reference fatigue life: approximately 5,000 fully loaded lifts for a forged hook).

Quarterly: Calibrate the hook pulley assembly for alignment (to prevent unilateral wear of the hook due to uneven loading).

Crawler crane hooks are not “consumables” but “safety assets” that require meticulous management. Choosing the right types of crane hooks is fundamental, proper maintenance is crucial, and regular inspections are essential. By following these three guidelines, your crawler crane operations will be free from over 90% of hook-related risks.

Shandong Value Machinery Manufacture Co., Ltd. is a high-tech enterprise specializing in the research, development, and manufacturing of crawler crane undercarriage parts. It is committed to providing high-performance crane parts to customers worldwide.