How To Choose Quality Kobelco Crawler Crane Parts?

In the heavy-duty construction machinery sector, Kobelco crawler cranes, with their powerful lifting capacity, exceptional maneuverability, and stability in complex working conditions, have become a core piece of equipment in construction and engineering. The key to ensuring the continued efficient operation of this equipment lies in selecting the right components—particularly the chassis system. This article provides an in-depth analysis of the core component composition and selection criteria for Kobelco crawler crane parts, along with recommendations for professional suppliers.

Kobelco Crawler Crane Core Parts

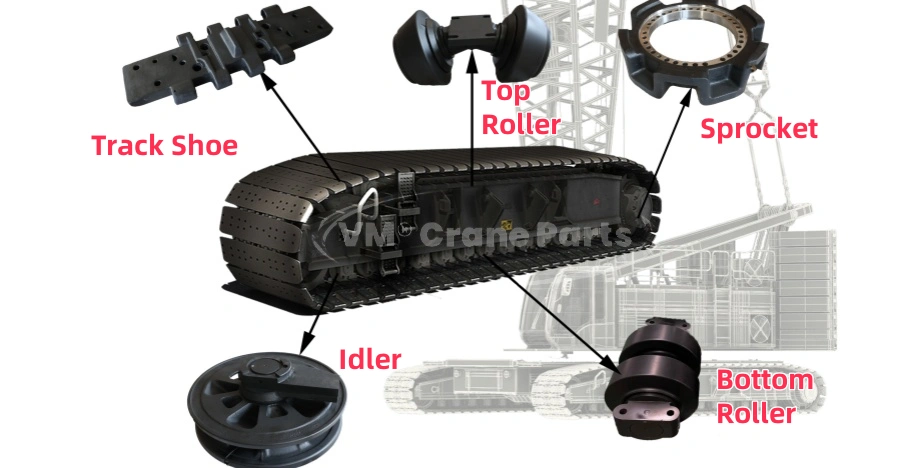

Kobelco Crawler Crane Undercarriage Parts

Track Shoes: These track shoes directly contact the ground, distributing the equipment’s weight through their wide surface area and reducing ground pressure. Made of OEM-grade material, Kobelco crawler shoes are suitable for machines with a lifting capacity of up to 1,350 tons. They offer excellent wear resistance and precise alignment, ensuring stability in complex terrain such as mud and gravel.

Bottom Rollers: Located at the bottom of the chassis, they support the crane’s weight and reduce friction between the crawler tracks and the ground. Its high-quality floating seal design and pure copper bushings adapt to various operating conditions, effectively extending its service life while strictly controlling the risk of cracks.

Idler: Optimized design guides the crawler chain and maintains tension, reducing chain slack and wear. Equipped with highly wear-resistant bronze bushings and long-lasting floating seals (with a service life exceeding 3,000 hours), they enhance the overall stability of the undercarriage.

Sprocket: Engages with the crawler chain, transmitting power to the machine for movement. Its superior design and high-quality materials withstand high stresses, ensuring efficient and stable power transmission.

Complete Machine Spare Parts

Electrical Components: These include wiring harnesses, sensors, switches, and control panels. These components form the “nerve center” of the equipment, controlling and monitoring various crane functions to ensure safe and efficient operation.

Hydraulic Components: Such as cylinders, pumps, valves, and hoses, power the crane’s lifting, retracting, and rotating movements. Their performance directly impacts the equipment’s operating accuracy and efficiency.

Available Kobelco Crane Parts:

The following are the popular Kobelco crane parts we can provide:

1.Kobelco CKE2500G JD71A01001D1 PIN-GUY CABLE

2.Kobelco CKE2500G ZP16D10090 SPLIT PIN-GUY CABLE

3.Kobelco CKE2500G LS21P01019F1 FUEL FILTER ASSEMBLY

4.Kobelco CKE2500G JD61F01013F1 SHEAVE ASSY -GANTRY

5.Kobelco CKE2500G JL06A01012F1 SHEAVE ASSY-GANTRY & MAST ASSY

6.Kobelco CKE2500G GG62A00007F3 SHEAVE ASSY AUX

7.Kobelco CKE2500G GG73A00006S006 SHEAVE-MAIN HOOK

8.Kobelco CKE2500G JJ73A01001F1 STOPPER-MAIN HOOK

9.Kobelco CKE2500G GG73A00006S022 BEARING-MAIN HOOK

10.Kobelco CKE2500G GN02P01037P1 BELLOWS

11.Kobelco CKE2500G GN02P01007P1 INTER COOLER HOSE-OUTLET

12.Kobelco CKE2500G GN02P01008P1 INTER COOLER HOSE-INLET

13.Kobelco CKE2500G GN02P01012P1 HOSE-TURBO

14.Kobelco CKE2500G 2414T3543 PLATE-ENGINE MOUNTING

15.Kobelco CKE2500G 2416R155 RUBBER-ENGINE MOUNTING

16.Kobelco CKE2500G 2416R295 ENGINE RUBBER MOUNTING

17.Kobelco CKE2500G ZW13H20000 WASHER-ENGINE MOUNTING

18.Kobelco CKE2500G ZS13C20130 CAPSCREW-ENGINE MOUNTING

19.Kobelco CKE2500G ZN13C20016 NUT-ENGINE MOUNTING

20.Kobelco CKE2500G ZC15X10500 CLIP-TURBO HOSE

21.Kobelco CKE2500G 2446Z143 STRAINER -FUEL PUMP

22.Kobelco CKE2500G JJ15V01002F1 PLUG ASSY-WINCH MOTOR

23.Kobelco CKE2500G 24846Z2 BREATHER-HYDRAULIC TANK

24.Kobelco CKE2500G 2444Z3305 BREATHER-WINCH MOTOR

25.Kobelco CKE2500G 2414U116D2 CAP FILLER-HYDRAULIC

26.Kobelco CKE2500G GG51C01021F1 ARM ASSEMBLY- CAB DOOR

27.Kobelco CKE2500G GB50C01025P1 ROLLER-CAB DOOR

28.Kobelco CKE2500G GG51C01003F1 LOCK ASSEMBLY-CAB DOOR

29.Kobelco CKE2500G ROLLER ASSY-INSERT BOOM 24100N3581F3

Kobelco Crawler Crane Parts Selection

Compatible Device Models

Kobelco offers a vast range of crawler crane models, from the compact BM series to the larger CKE series. These models vary significantly in structural design and load-bearing capacity:

- Small models (such as the P&H330) are designed for operation in confined spaces, requiring components tailored to their compact chassis, such as smaller track shoes and lightweight rollers.

- Large models (such as the P&H7055) are designed for heavy-duty operations, requiring components with enhanced structural strength, such as thicker track shoes and high-strength drive gears.

Preferred Material Quality

The material used in a component directly determines its performance and lifespan. Kobelco and its high-quality suppliers adhere to strict standards in material selection:

- High-strength steel alloys (such as S690QL and T-1 steel) are used in key structures such as the boom and frame, providing high tensile strength and impact resistance.

- Manganese steel is used in high-wear components such as track shoes and rollers, enhancing wear resistance and reducing maintenance frequency.

- Stainless steel is used in parts exposed to moisture or corrosive environments (such as fasteners) to prevent rust.

- Heat-resistant alloys are used in high-temperature components such as engines and exhaust systems to ensure stability in extreme temperatures.

- Aluminum alloys are used in components that require weight reduction, such as boom extensions, to improve lifting efficiency while maintaining strength.

Matching the Operating Environment

The operating environment of the equipment significantly affects component wear, so specific considerations should be taken into account when selecting the right equipment:

- Dusty/abrasive environments (such as construction sites and mines): Prioritize highly wear-resistant track rollers and track shoes, such as those made of manganese steel, to resist abrasion from dust and debris.

- Swampy/muddy terrain: Choose wide, self-cleaning track shoes (such as those with mud holes) to enhance traction and prevent mud accumulation.

- Coastal/marine environments: Choose stainless steel or anti-corrosion-coated track chains to resist saltwater corrosion and extend the life of the chassis.

Recommended Professional Supplier: VM® Track Parts

To ensure the quality and compatibility of Kobelco crawler crane parts, selecting a professional supplier is crucial. VM®, a manufacturer specializing in Kobelco crane undercarriage parts, offers significant advantages:

- Full-Line Coverage: We offer a full range of undercarriage components, including track shoes, rollers, carrier sprockets, idlers, drive wheels, and track chains, compatible with nearly all Kobelco BM, CK, CKE, and P&H models.

- OEM-Grade Quality: We strictly adhere to original manufacturer specifications, using materials and craftsmanship that match OEM standards to ensure precise fit and stable performance. For example, the wear resistance of track shoes and the sealing performance of rollers meet OEM standards.

- Full-Process Quality Control: All parts undergo rigorous testing, from material procurement to production and processing, and finished product inspection, ensuring reliability under harsh operating conditions.

- Efficient Supply Chain: Leveraging advanced production facilities and supply chain management systems, we enable a timely response to demand, ensuring timely parts supply and minimizing equipment downtime.

Contact:

Whatsapp:+86 15253585909

Email:info@cranecrawler.com