Description

We specialize in producing IHI CCH800-2 crawler drive sprocket. The casting process combines overall quenching and tempering with surface hardening. We provide ISO9001 certification and quality inspection reports.

Product Description

| Brands | VM |

| Production information | Sprocket, Drive Tumbler |

| Process Technology | Casting |

| Heat Treatment | Whole quenching and tempering, surface hardening |

| Trade Terms | EXW, FOB, CFR, CIF |

| Certification | ISO9001 |

| Condition | New |

| Quality Inspection Report | Provide |

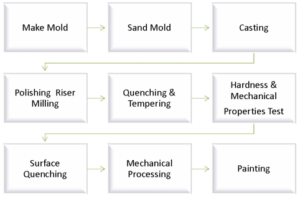

Production Process of IHI CCH800-2 Crawler Drive Sprocket

Testing of IHI Drive Sprocket :

1) Dimension Testing

Use precision measuring tools (e.g., calipers, micrometers, and gauges) to confirm that the IHI CCH800-2 drive sprocket’s dimensions align with the manufacturer’s specifications.

Check the teeth and spacing to ensure proper engagement with the track chain.

2) Hardness Testing

Perform hardness testing to ensure the sprocket meets the required hardness levels for wear resistance.

The IHI CCH800-2 sprocket should have a hardened surface to withstand the abrasive forces encountered during operation.

Reviews

There are no reviews yet.