Description

The Liebherr LR1250 Top Roller is a critical undercarriage component engineered to ensure smooth track movement and reduce friction in heavy-duty crawler crane operations.

Liebherr LR1250 Top Roller Key Specifications

| Model | Liebherr LR1250 Top Roller (Carrier Roller/Upper Roller) |

| Material | 50Mn |

| Heat Treatment | Quenching & Tempering + Surface Induction Hardening (HRC 50-56) |

| Condition | Brand New, OEM-Compatible |

| Warranty | 2,500 Working Hours or 1 Year |

| MOQ | 1 Piece |

| Lead Time | 7-25 Days After Payment Confirmation |

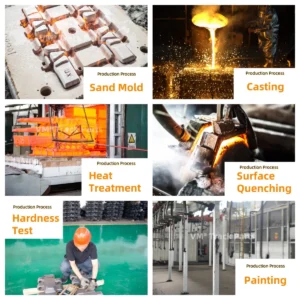

Production Process Of Liebherr LR1250 Top Roller

Advantages

Ultra-Wear-Resistant Design

42CrMo Alloy Construction: Superior tensile strength and fatigue resistance under dynamic loads.

Surface Hardening: Induction-hardened outer layer (HRC 50-56) extends service life by 40% compared to standard rollers.

OEM-Standard Quality

100% raw material traceability and 3-step inspection (dimensional, hardness, load testing).

28+ years of expertise in crawler crane undercarriage manufacturing.

Customization Flexibility

Modify bore size, flange thickness, or material grade to match OEM specs.

Rapid Supply Chain

200+ units/month production capacity with emergency order prioritization.

Other Liebherr Crane Parts Model

HS852HD, HS855HD, HS895, HS833HD, HS843, HS843HD, HS853, HS853HD/VRM, HS882, HS883, HS872, HS885, HS895HD,HS830, HS832HD, HS840, HS841, HS842HD, HS851, HS851HD, HS870, HS871, HS873HD, HS993, HS8200HD, LR1100, LR1130, LR1160, LR1200, LR1250, LR1280, LR1300, LR1350, LR1400, LR1400-2, LR1550, LR1600, LR1600-2, LR1650, LR1750, LR11000, LR11350, LTR1100, LTR1220, LR1130, LTR1060, LB28, R974

Packaging & Logistics

Robust Export Packaging: Crates with moisture-resistant coatings and shock-absorbent fillers.

Global Delivery: Air/Sea/Rail options from major Chinese ports.

Contact Us for Immediate Support!

Email: info@cranecrawler.com

WhatsApp: +86 17853553781

Reviews

There are no reviews yet.