Description

As the key load-bearing component of the Nippon Sharyo DH700 chassis system, the VM factory carefully crafted a special Nippon Sharyo DH700 bottom roller, with excellent engineering design and strict manufacturing standards, that provides a long-lasting and stable operation guarantee for your construction machinery.

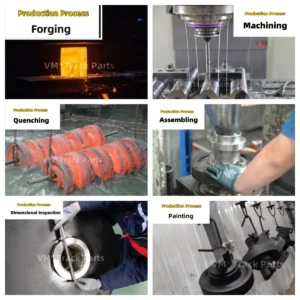

Production Process of Nippon Sharyo DH700 Bottom Roller

Nippon Sharyo DH700 Bottom Roller Advantages

Excellent wear resistance, doubled life

Excellent materials and processes: Selected high-quality 40Mn2 or 42CrMo alloy steel, formed by precision forging technology to ensure that the material is dense and defect-free.

Advanced heat treatment support: Applying the internationally leading heat treatment process, the Nippon Sharyo lower roller surface and core achieve an ideal hardness and toughness ratio, thereby obtaining the industry’s top wear resistance. Even under extremely harsh working conditions, it can significantly extend the service life and greatly reduce the replacement frequency.

Precision manufacturing, easy assembly

Accurate size guarantee: Each DH700 bottom roller produced by VM is precisely measured and fully tested by professionals to ensure that the dimensional accuracy is in full compliance with the original factory specifications.

Maximize equipment efficiency: The simplified maintenance process is designed to minimize downtime, help you quickly resume production, and improve equipment utilization.

Reviews

There are no reviews yet.