Description

Sumitomo SC1500 track shoe SGS certification | 2000-2500 hours of ultra-long service life. 15-day global delivery. Provide geological adaptability solutions.

Sumitomo SC1500 Track Shoe Specifications

Model certification SC1500 (SGS certification)

Applicable models: Kobelco SC1500 and compatible crawler crane chassis system

Basic material 35SiMn special alloy steel (military grade material selection)

Process technology: Precision casting + overall quenching and tempering + surface hardening

Service life 2,000-2,500 working hours (with material report)

Delivery time: 15 days, global express delivery (3,000+ inventory)

Available brands: Kobelco/Sumitomo/Hitachi/Liebherr and over 20+ other brands

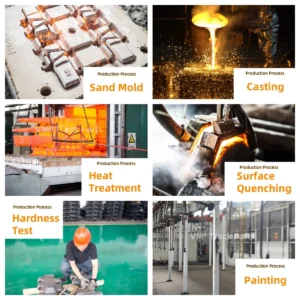

Production Process of Sumitomo SC1500 Track Shoe

Frequently Asked Questions

Q1 Can it be mixed with Kobelco original Sumitomo SC1500 track pads?

→ Provide a “Multi-brand chassis parts compatibility manual”, which contains bolt torque parameters, preload standards, and a mixed installation and debugging guide to ensure seamless cooperation with the original SX1500 system. Support video remote guidance installation.

Q2 Does special geology (such as frozen soil/desert) require adjustment of track plate spacing?

→ Free geological adaptability package:

- Including geological hardness testing tools

- Track plate spacing adjustment calculation template

- Free special cleaning tools to prevent sand and stone from jamming

Q3 How to determine whether the track plate needs to be replaced?

→ 3-step quick self-test method:

- Tooth wear: Tooth height wear > 8mm (with free inspection caliper)

- Crack detection: Use a penetrant flaw detector (gifted with goods)

- Chain deformation: Straightness deviation > 2mm/meter needs to be replaced

Q4 Is the warranty policy valid under extreme working conditions?

→ Provide graded protection during the warranty period (2,000-2,500 hours):

- Normal working conditions: Free replacement for non-human damage

- Heavy load environments such as mines/polar regions: Enjoy extended warranty to 1,500 hours

- Provide a working condition record sheet template to assist users in standardizing maintenance records

Q5 How to verify whether the product meets the original factory standards?

→ Provide full-process quality files:

- Material spectrum analysis report (SGS certified)

- 3D scanning comparison chart (tolerance ≤ 0.1mm)

- Dynamic load test video (simulating 10,000 hours of working conditions)

Reviews

There are no reviews yet.