Blog Single

Most of the crawler cranes undercarriage parts are made of alloy steel, and common production processes are forging and casting. To ensure the quality and extend the service life of the parts, multiple inspections are required during the production process to prevent forging or casting defects from affecting their performance.

Common challenges and wear issues of crawler crane undercarriage parts

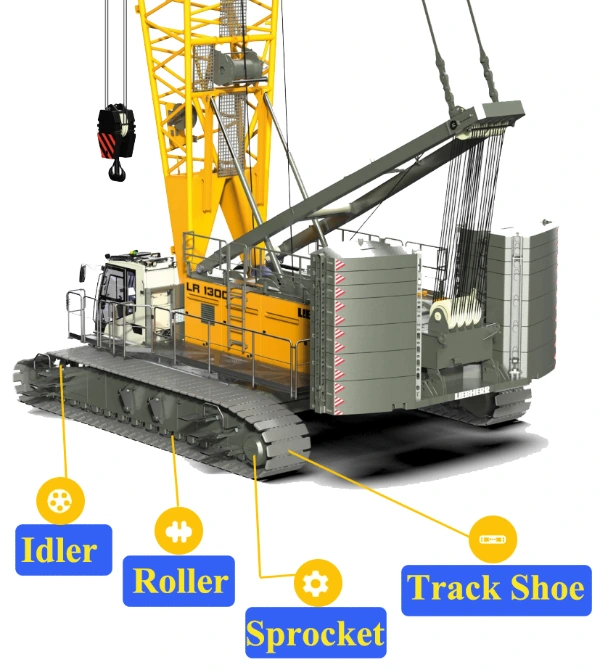

The crawler crane undercarriage parts including track shoes, rollers, sprockets, and slewing bearings, are critical to the crane’s performance. These parts must support the crane’s weight and endure prolonged, intense operations. Their wear resistance and reliability are vital due to the demanding conditions they operate in.

Harsh environments and heavy loads lead to common challenges like excessive wear on track shoes, idlers, rollers, sprockets, and wheels, often caused by abrasive surfaces and frequent load changes. Improper maintenance can result in uneven wear, affecting the crane’s stability and efficiency. Besides, exposure to moisture, mud, and corrosive chemicals accelerates corrosion, reducing the parts’ work life.

To combat these issues, thorough inspections during production are essential, ensuring high-quality parts and prolonging their service life. Regular maintenance, proper lubrication, and timely replacement of worn crawler crane undercarriage parts are crucial to optimal performance. are critical to the crane’s performance.

Types of Testing for Crawler Crane Undercarriage Parts

1. Chemical composition analysis

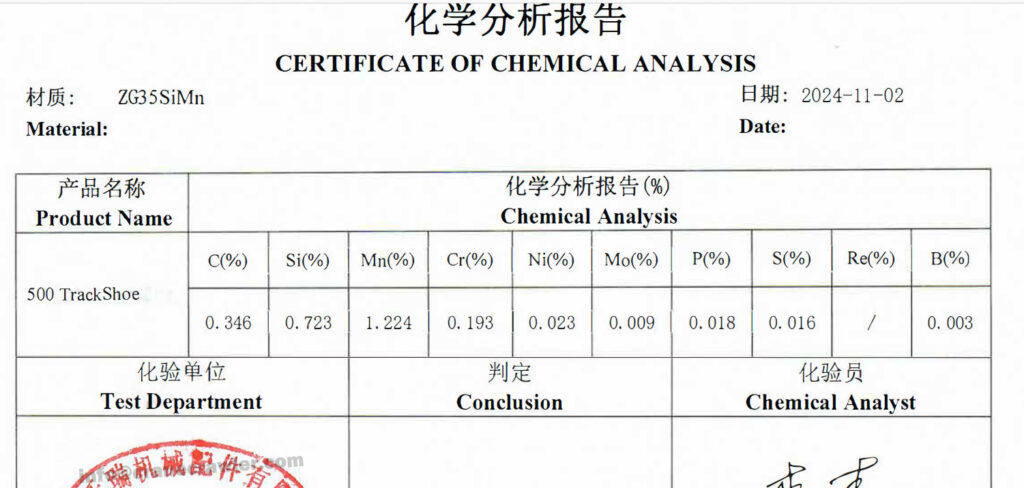

Chemical composition analysis is a vital part of forging and casting because it directly determines the quality, performance, and reliability of crawler crane undercarriage parts. Compositional analysis allows the chemical makeup of an accessory to be accurately detected, ensuring that the product meets specific standards, application needs, and performance requirements. Correct composition analysis can avoid material defects and substandard performance, ensuring the stability and durability of accessories in use.

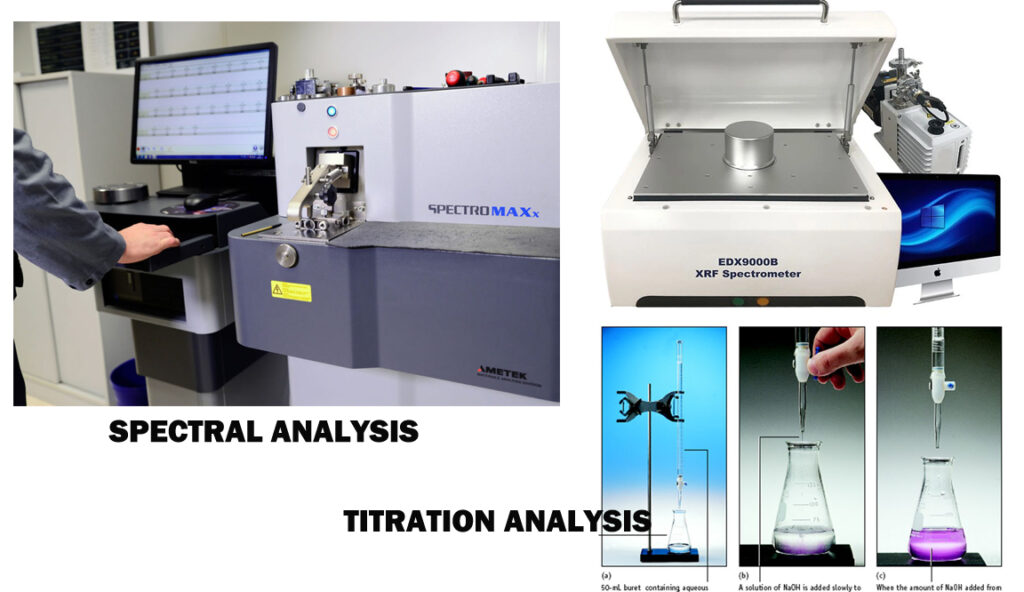

When raw materials are poured out from the furnace, samples are taken for chemical composition analysis. Common methods for this analysis include spectral analysis, titration analysis, and X-ray fluorescence (XRF).

Spectral analysis provides rapid and precise data on elemental composition, titration uses reactions to quantify elements, and XRF offers non-destructive testing by analyzing the material’s response to X-ray excitation. These methods effectively detect key elements of crawler crane undercarriage parts such as carbon(C), silicon(Si), manganese(Mn), Phosphorus(P), and sulfur(S), enabling a comprehensive evaluation of the material’s chemical makeup to ensure compliance with technical requirements and industry standards.

2. Mechanical testing evaluates properties

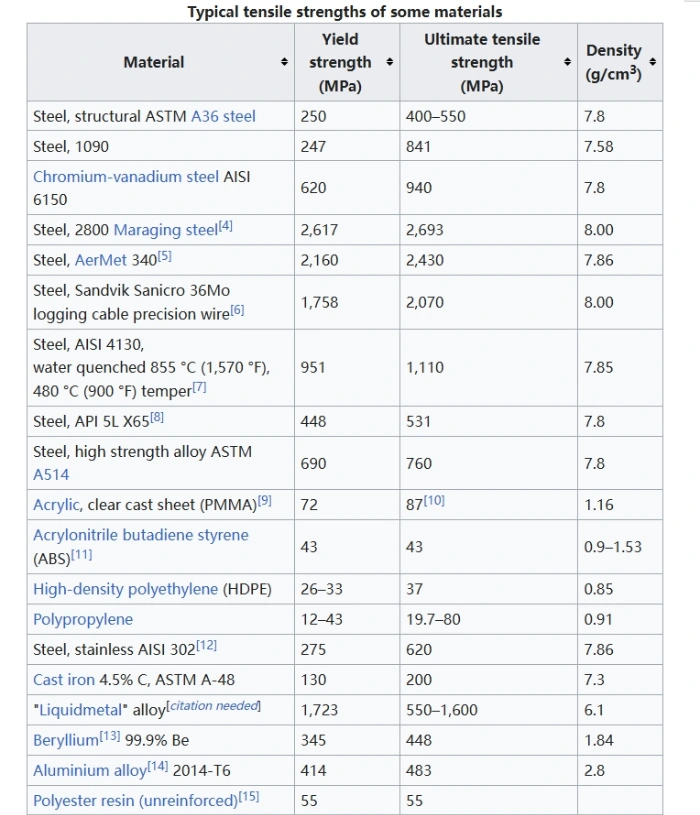

Mechanical testing evaluates properties such as Ultimate tensile strength, bending tensile, yield strength, and hardness, all of which are critical to a crawler crane undercarriage part’s durability and safety in use.

Here’s why it’s done:

Strength and Hardness

Testing these ensures the undercarriage parts can handle external forces and resist wear and tear during operation. It verifies whether the product meets quality and safety standards.

Toughness and Plasticity

These tests assess the undercarriage part’s ability to absorb impact without breaking (toughness) and its ability to deform under stress (plasticity). These factors ensure the part’s long-term reliability in different conditions.

Defect Identification

Mechanical tests can detect hidden issues like cracks, air pockets, or impurities in the material. Addressing these early helps maintain product quality and performance.

Common mechanical testing methods are used to assess different properties of materials and components. Here are some of the key methods explained in simple terms:

Tensile Testing

Tensile testing measures a material’s strength, toughness, and flexibility. It involves pulling a sample apart under controlled conditions to see how much force it can take before breaking. Key results include yield strength (the force needed to cause permanent deformation), tensile strength (the maximum force the material can endure), and elongation (how much it stretches before breaking).

From: www. wikipedia.org/wiki/Ultimate_tensile_strength

Bending Testing

Bending tests measure a crawler crane undercarriage part’s ability to resist deformation or fracture under a bending force. This test is particularly useful for components that must withstand flexing. Results include bending strength and modulus, which indicate how well the material can perform under stress.

Each of these tests is tailored to specific performance indicators and material types, ensuring the reliability and safety of components in their intended applications.

Hardness Testing

This method evaluates a material’s hardness and surface durability by pressing or striking its surface with a specific force. It helps determine how resistant the material is to scratches or dents. Common measures include Brinell hardness, Vickers hardness, and Rockwell hardness, each suited for different types of materials and conditions.

The crawler crane undercarriage parts-top roller for reference:

Impact Testing

Impact testing assesses a crawler crane undercarriage part’s ability to withstand sudden forces or shocks without breaking. It involves striking a sample with a pendulum or hammer and measuring the energy absorbed before failure. This test provides data on toughness and impact strength, helping ensure the material’s reliability in dynamic environments.

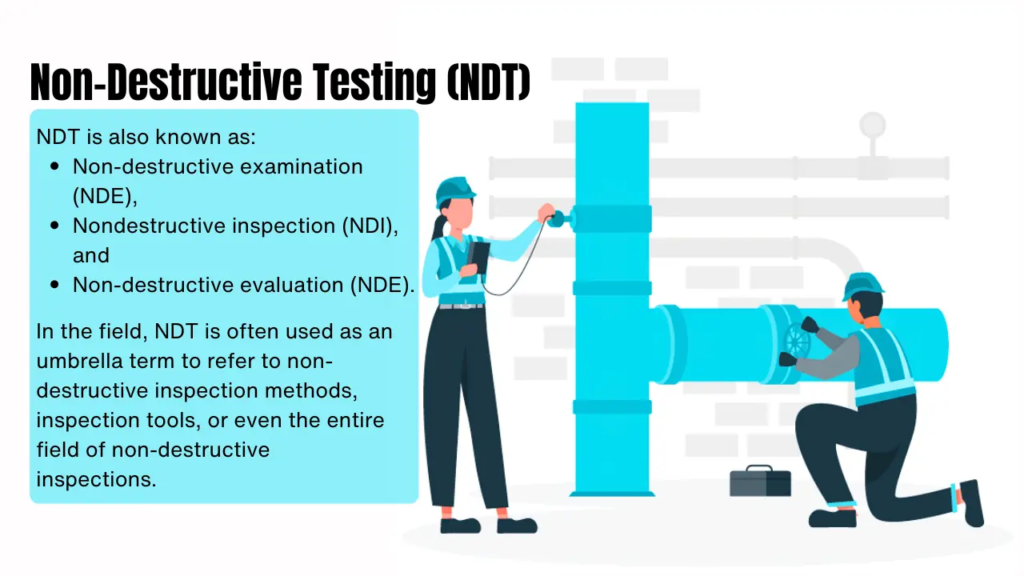

3. Nondestructive testing (NDT)

NDT is a method used to inspect the internal and surface structure of a crawler crane undercarriage part without being Nondestructive and affecting its performance or usability. It detects defects by analyzing changes in material reactions such as heat, sound, light, electricity, or magnetism.

NDT ensures the integrity of the product by allowing a complete inspection without causing damage. This method is highly effective for identifying flaws like cracks, voids, or irregularities, ensuring 100% coverage and eliminating the risk of missing defects that might occur with destructive testing methods.

Common non-destructive testing (NDT) methods include radiographic testing (RT), ultrasonic testing (UT), liquid penetrant testing (PT), magnetic particle testing (MT), and eddy current testing (ECT)

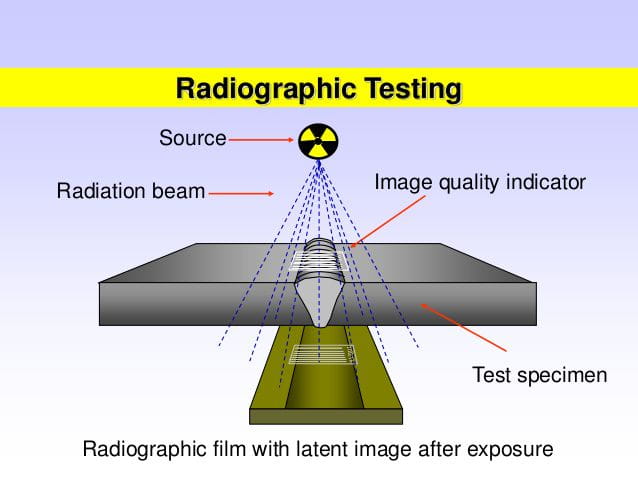

Radiographic Testing (RT)

Uses X-rays or gamma rays to penetrate materials and capture internal defects on film. It’s one of the most widely used NDT methods. For standard production, 20% of crawler crane undercarriage parts in each batch typically undergo RT inspection.

Ultrasonic Testing (UT)

Employs ultrasonic waves to detect internal defects, measure geometry, and assess structural changes in materials. It is highly sensitive and suitable for detecting small flaws in cast or forged crawler crane components.

Liquid Penetrant Testing (PT)

Commonly applied to cast crawler crane undercarriage parts like track shoes. A dye penetrant is applied to the surface, which seeps into open defects. Excess penetrant is removed, and a developer highlights the flaws under specific lighting conditions, revealing their shape and distribution.

Magnetic Particle Testing (MT)

Involves magnetizing ferromagnetic materials to identify surface or near-surface flaws. Magnetic powder accumulates at defect sites, forming visible indications that reveal the defect’s position and size.

4. Destructive Testing Methods -Cutting Tests

Involves cutting finished crawler crane undercarriage parts into sections to inspect their internal conditions. This method identifies issues such as wear, scratches, sand holes, pinholes, cracks, deformations, or reduced hardness. Standard production processes typically require cutting tests on 5% of the batch.

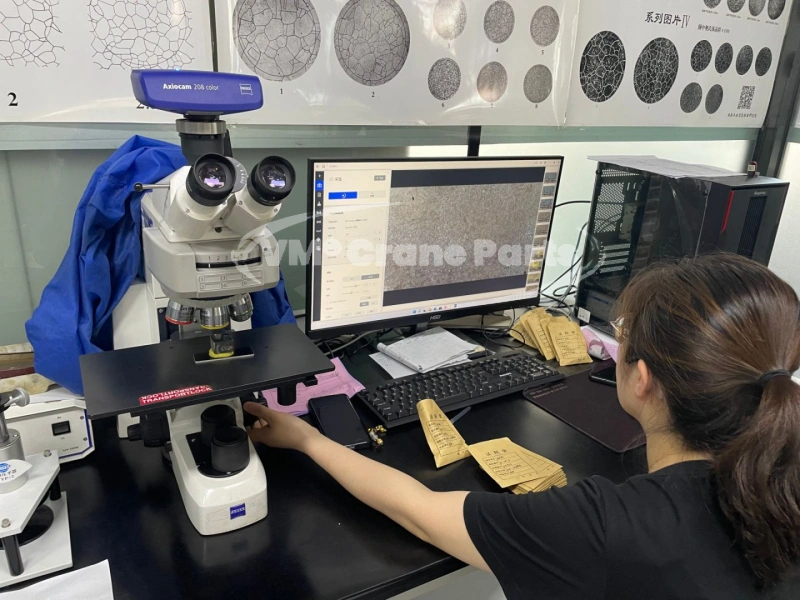

5. Metallographic Testing

Examines the relationship between a metal’s physical and mechanical properties and its internal structure through macroscopic and microscopic observations:

Macroscopic Structure Testing focuses on visible surface irregularities, such as cracks or voids, and assesses material cross-section defects and inhomogeneities.

Microscopic Structure Testing analyzes changes in metal structures caused by processing methods like rolling, forging, or heat treatment. This includes grain size, distribution of non-metallic inclusions, and material failure characteristics.

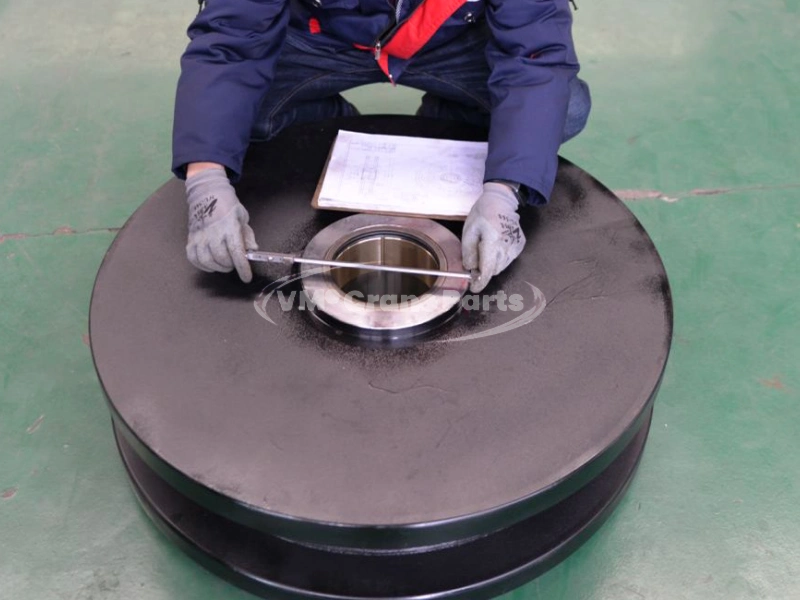

6. Sizes Inspection

Measures whether the dimensions of finished undercarriage parts align with the production drawings, ensuring tolerances remain within acceptable limits. The process measures and verifies whether the dimensions of the finished undercarriage parts align accurately with the production drawings. This ensures that all critical measurements—such as length, width, height, and specific geometric features—match the specified requirements. Additionally, it confirms that the parts fall within the defined tolerance limits, which are essential to maintaining the functionality and durability of the undercarriage components. This quality control step helps prevent any deviations that could affect the performance or safety of the final product. By closely monitoring these aspects, we ensure that only parts meeting the highest standards are approved for shipment, contributing to the overall reliability of the machinery in the field.

7. Running-In Tests

Simulates actual operating conditions by running parts under specific loads and speeds for a set period. This test evaluates the performance, wear resistance, and service life of the parts, ensuring they meet quality standards before use.

Whether it is non-destructive testing or damage testing, these tests are a key step in ensuring the quality and performance of crawler crane undercarriage parts. They are able to identify internal defects, surface defects, and performance deviations of materials to avoid safety hazards or equipment failures due to quality issues. At the same time, the reliability of the production process can be verified through testing, and the service life and stability of the crawler parts can be improved. Strict testing not only won the market reputation for the manufacturer but also provided confidence for users.

Besides, to ensure efficient crawler crane operation, quality design and manufacturing alone is not enough. Systematic testing is essential to help identify and correct problems early and minimize potential risks. By adhering to a rigorous inspection process, we can not only reduce the downtime caused by component failures but also extend the service life of the equipment, thereby reducing the overall operating cost and providing users with a stable and efficient operating experience.